DUCTING EXPANSION JOINTS

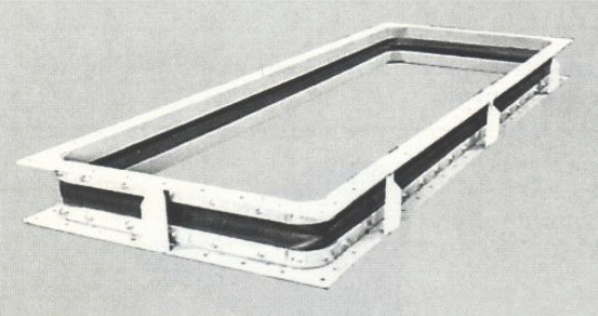

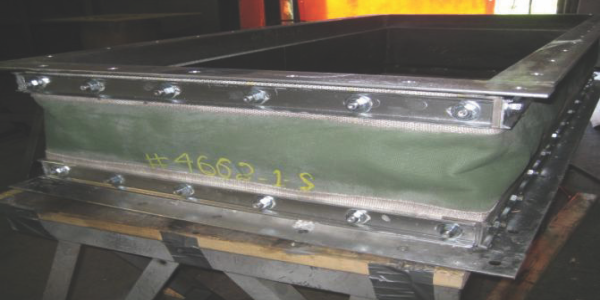

Bachmann Dampjoint Model “C” fabric expansion joint is a general purpose flexible connector offering the convenience of metallic attachment flanges with a belted type flexible element.

When vertical, horizontal & lateral movement are present

Rugged metallic flanges allow the choice of either welded or bolted installation. Since the flanges are designed for a lifetime of service, welded installation, which eliminates all bolt holes and gasket seepage problems, becomes very practical.

- Economical

- Low cost installation welded or bolted

- Easy fabric replacement

- Minimal spring rates

- Noise reduction

- Vibration isolation

- Rectangular, square or round configuration

- Optimized utilization of fabric element