DUCTING EXPANSION JOINTS

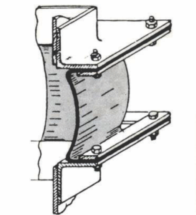

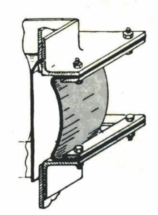

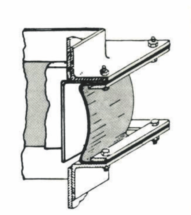

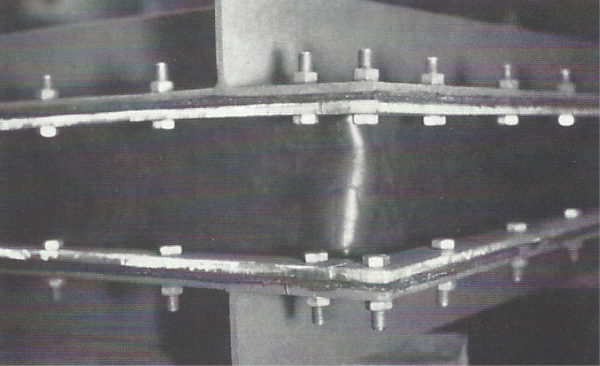

Bachmann Dampjoint Model “U” style expansion joints feature low stress, integrally molded reinforced corners; thus, the joints require only one longitudinal splice. Along with its integrally moulded flanges, the model “U” is your optimum choice for applications, where elastomers can be used in direct contact with the media, without internal protective liners.

When vertical, horizontal, & lateral movement are present

Features and Benefits:

- Maximum active expansion joint between flanges, hence optimum flexibility

- Elimination of Corrosion-affected hardware

- Rectangular, Square, or Round Configuration

- Minimal Spring Rates

- Self-Sealing

- Economical

- Low-cost installation

- Easy Replacement

- Noise Reduction

- Vibration Isolation